LMC50 JAW CRUSHER USER MANUAL - Laarmann

2021.3.10 ving jaw plate. Designed for the smaller laboratory, or use by prospectors. It is capable of quickly crushing materials up to 85% of the jaw opening (65 mm x 65 mm). It is robust and long wearing and made of parts and materials easily serviced in a remote

consulter en ligne

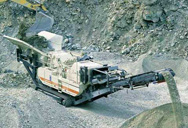

QH441-OperationManual - Crusher Works

2015.11.6 39 Item Part No. Image 1 DE1007 2 DE6000 3 DE6004 4 DE6015 5 DE6006 DE5024 6 DE6007 7 DE0027 tagout)

consulter en ligne

Influence of jaw crusher parameters on the quality of

2020.6.1 A parameter study using a jaw crusher is designed to investigate the influence of feed gradation, feed rate, crusher setting and crusher speed on the crusher operation and the quality of the produced aggregates.

consulter en ligne

(PDF) Influence of jaw crusher parameters on the

2020.3.19 PDF A parameter study using a jaw crusher is designed to investigate the influence of feed gradation, feed rate, crusher setting

consulter en ligne

ANALYSIS OF ENERGY CONSUMPTION OF CRUSHING

materials energy consumption in the two-stage crushing process was reduced by 30%. Key words: rock crushing, jaw crusher, crushing efficiency, two stage crushing process 1. INTRODUCTION The main aim of processing rock raw materials is to prepare and process the rocks to a condition that meets the commercial requirements for quality parameters as

consulter en ligne

Optimizing processing parameters of stone crushers through

2022.1.1 Present paper showcase the optimization of crushing parameters through Taguchi methods to improve the production yield of the aggregate produced. The main objective is to investigate the impact of various crushing parameters like feed rate to jaw crusher and eccentric speed of Jaw crusher, closed side setting and throw in cone crusher.

consulter en ligne

Evaluating the Impacts of Jaw Crusher Design

2020.2.28 . Abstract—In mineral processing, to obtain the desired particle size, aka liberation size, comminution is applied. This process may involve both crushing and grinding operations. The primary crushers handles the size reduction of the run of mine with maximum particle size and capacity.

consulter en ligne

Industrial Solutions Jaw crushers - ThyssenKrupp

2022.11.21 The single-toggle jaw crusher with the largest antifriction bearings and highest flywheel energy 1) with new crushing elements 2) ... Serrated jaw plates enhance the crushing process. When the 200 250 300 350 400 1,600 1,400 1,200 1,000 800 600 400 200 Throughput [t/h] 0 Crushing capacity • with primary

consulter en ligne

Modeling and Improving the Efficiency of

2023.5.16 The authors of the study suggested an automatic process control system for a jaw crusher. This would improve and intensify the production process while reducing human intervention by solving

consulter en ligne

SANDVIK JAW CRUSHER SERIES - Sandvik Mining and

2020.4.1 The Sandvik jaw crusher line is designed for the motor sizes listed in RPG and technical specifications. This means that for harder materials, the crusher will have to be operated at larger settings to avoid overload of drive and/or motor. Using oversized motors will lead to radically shorter crusher life and various mechanical problems.

consulter en ligne

Jaw Crusher: Range, Working Principle,

2022.2.22 Jaw crushers are used as primary crushers, or the first step in the process of reducing rock. They crush primarily by using compression. The rock is dropped between two rigid pieces of metal, one

consulter en ligne

Introduction to Jaw Crushers: Understanding the Basics

2023.12.30 These plates play a crucial role in the crushing process by connecting the movable jaw to the rest of the crusher. They also provide an adjustable point to control the size of the crushed material ...

consulter en ligne

(PDF) Experimental and Numerical Studies of Jaw

2013.9.10 The jaw crusher angle and rotating mass type are considered to study all particle sizes and reduction ratios obtained for three different motor operation speeds: 1500, 2000, and 2500 rpm.

consulter en ligne

Jaw Crusher: What Is It How Does It Work? - Vykin

5 天之前 A jaw crusher is a machine that breaks down large rocks into smaller pieces of rock, gravel, or dust. It does this by placing two jaw plates perpendicular to each other and squeezing the rock between them until it is broken into small pieces. A stationary jaw plate and a movable jaw plate control the movement of these jaw plates.

consulter en ligne

Understanding Jaw Crusher Parts and Their Functions - AGICO

2023.2.23 Introduction: Jaw crushers are powerful machines that are widely used in the mining, quarrying, and recycling industries. These machines are designed to crush large rocks and ores into smaller pieces for further processing. A jaw crusher consists of a fixed jaw and a movable jaw, with the latter being driven by an eccentric shaft that moves the

consulter en ligne

Influence of jaw crusher parameters on the quality of

2020.6.1 A parameter study using a jaw crusher is designed to investigate the influence of feed gradation, feed rate, crusher setting and crusher speed on the crusher operation and the quality of the produced aggregates. The study is focused on the production of all-in large-size (top size ⩾90 mm) aggregates, suitable for use in subbase

consulter en ligne

What is the role of 'jaw crusher' in the construction industry ...

2023.9.30 Q2: What are the key components of a jaw crusher? The main components of a jaw crusher include the fixed jaw, the movable jaw, the pitman (eccentric shaft), toggle plates, and the motor. The movable jaw exerts force on the material by pressing it against the fixed jaw, crushing it in the process. Q3: What types of materials can jaw crushers

consulter en ligne

A Guide to Types of Jaw Crushers for Crushing Rocks and

2023.2.15 A gyratory crusher is a type of crusher that uses a mantle to guide the crushing process. The mantle is suspended on an eccentrically rotating shaft, which causes the mantle to gyrate. The gyratory crusher has a higher capacity than a jaw crusher. It is often used for primary crushing in the stone crushing industry.

consulter en ligne

A fundamental model of an industrial-scale jaw crusher

2017.5.1 Abstract. In this study, an analytical perspective is used to develop a fundamental model of a jaw crusher. Previously, jaw crushers were modelled in regard to certain aspects, for example, energy consumption (Legendre and Zevenhoven, 2014) or kinematics (Oduori et al., 2015). Approaches to date have been mainly property specific.

consulter en ligne

What Is A Jaw Crusher? - Caldas Engineering and

A jaw crusher primarily consists of two plates: the fixed jaw plate and the movable jaw plate. The key to its operation is the reciprocating movement of the movable jaw plate, reminiscent of our very own jaw’s motion when we chew. This physical process exerts sufficient force on the input material, often large chunks of rock or ore, causing ...

consulter en ligne

Crushing Plant Startup Sequence Procedure

2016.1.26 Start the dust collector. Scrubber bottoms pump will start automatically. Place sump pump on AUTOMATIC. Start either cone crusher lube pumps and allow 5 seconds for pressure to build up and oil to be

consulter en ligne

Primary Jaw Crusher – Everything You Need to Know

2023.2.28 A primary jaw crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust. It is used in many industries, including mining, construction, and demolition, to crush

consulter en ligne

Assessing the energy efficiency of a jaw crusher - ScienceDirect

2014.9.1 Abstract. It is well known and taken for granted that the efficiency of energy use by comminution (i.e. breaking, crushing, grinding) equipment is very low, typically less than 10%. Most of the process input power is dissipated as heat and noise and ineffective deformation of the material to be processed and the device itself.

consulter en ligne

Jaw Crusher - an overview ScienceDirect Topics

The ore is to be broken down in a jaw crusher to pass through a 11.5 cm screen. The undersize is scalped before feeding to the jaw crusher. Assuming the maximum feed rate is maintained at 30 t/h and the shapes of feed and product are the same and the crusher set is 10 cm, estimate the size of jaw crusher required and the production rate. Solution

consulter en ligne

sbm/sbm mmissioning crushing plant lessons learned.md at

You've already forked sbm 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity

consulter en ligne

Below the surface: Setting up an underground primary jaw crusher

2014.4.1 Jaw crushers are the most common solution in underground applications when the throughput is below 1000 tonnes per hour, depending somewhat on the scalping solutions. Above 1000 tph, primary gyratory crushers are an option. After the throughput reaches 2000 tph, jaw crushers are very rare, with the exception of a parallel plant layout.

consulter en ligne

Primary Crusher vs. Secondary Crusher: Understanding Their

2023.2.28 The jaw crusher works by moving the material between a fixed and a moving plate. The moving plate applies force to the material, causing it to break down into smaller pieces. The gyratory crusher, on the other hand, uses a mantle and concave surfaces to compress the material. ... Without a primary crusher, the entire process of

consulter en ligne

Investigation of vibrating jaw crusher experimental variables

2023.9.30 The jaw crusher angle and rotating mass type are considered to study all particle sizes and reduction ratios obtained for three different motor operation speeds: 1500, 2000, and 2500 rpm.

consulter en ligne

“Design and Analysis of Swing Jaw Plates of Jaw Crusher

The objective of the present work is to study for a design and analysis of commercially available swing jaw plates that is 0.9 m (36 in.) wide with 304 mm and 51 mm top and bottom openings of jaw crusher. The finite element method is applied to the analysis of the swing jaw plate.

consulter en ligne

What is a PE Jaw Crusher? Jaw Crusher

2022.5.24 2720×1950×1600. PE/PEX jaw crusher series is usually called as Jaw Crusher and is a crushing appliance that was produced relatively early. and it is generally regarded as the primary breaker and is applied to various stone production lines and ore reduction production lines, due to simple construction, solidness, reliable working, easy ...

consulter en ligne

Understanding Types of Jaw Crusher: A Comprehensive

2024.2.6 Blake jaw crushers, also as double toggle jaw crushers, are characterized by the position of the pivot of the swing jaw, which is located at the top of the machine. This design allows for a larger feed size and a higher capacity, making it suitable for primary crushing. The motion of the swing jaw in a Blake crusher is predominantly vertical ...

consulter en ligne

Bond Impact Crushing Work Index -Procedure and

2015.6.16 The test determines the Bond Impact Work Index which is used with Bond’s Third Theory of Comminution to calculate net power requirements when sizing crushers*. It is also used to determine the

consulter en ligne

7 Differences Between Jaw Crusher and Impact Crusher

2024.5.11 5. discharge fineness. Jaw crusher, as coarse crushing equipment, has larger discharge fineness, usually below 300-350mm (depending on the model). Impact crusher, as medium or fine crushing equipment, naturally has smaller discharge fineness. Here, we should notice that due to different material properties, the discharge fineness

consulter en ligne

Failure analysis of jaw crusher and its components using

2015.7.1 Fig. 8 Surface plot of a jaw crusher, b back toggle plate, c chute liner plate, d jaw plate and e and tie rod Author's personal copy J Braz. Soc. Mech. Sci. Eng.

consulter en ligne

Advantages and Disadvantages of Jaw Crusher

2023.9.24 Ⅰ. Introduction. 1.A brief introduction to jaw crusher. Jaw crusher is a common mining machinery equipment, mainly used for coarse crushing of ores and bulk materials of various hardnesses. It has two jaw plates, one fixed jaw plate, called the fixed jaw plate, and the other movable jaw plate, which is driven by an eccentric shaft so that

consulter en ligne

“Computer Aided Design of Jaw crusher” - 911 Metallurgist

2016.12.19 Jaw crusher movement is guided by pivoting one end of the swinging jaw. and an eccentric motion located at the opposite end. [4] The size of a jaw crusher is designated by the rectangular or square opening at the top of the jaws .For instance, a 22 x 30 jaw crusher has an opening of 22" by 30", a 46 x 46 jaw crusher has a opening of 46"

consulter en ligne

EXPERIMENT:- Jaw Crusher

2022.8.24 The work index includes the friction in the crusher and the power given by above eq is gross power PROCEDURE: • Start the jaw crusher and find the power consumption under no load condition with the help of energy meter and a stop watch. • Prepare the sample you want to crush in the jaw crusher.

consulter en ligne

Development of a New Generation High Crushing Capacity Jaw Crusher

2023.12.31 A jaw crusher is a kind of size reduction machine which is widely used in mineral, aggregates and metallurgy fields. ... Modelling of crushing process in jaw crushers allows to maximally optimize ...

consulter en ligne

Introduction to Jaw Crushers: Understanding the Basics

2023.12.30 The foundation of a jaw crusher is the frame, which provides structural support and houses the eccentric shaft, which is a critical component for generating crushing motion. Eccentric Shaft:

consulter en ligne

Nordberg® C Series™ jaw crushers - Metso

The core of Nordberg® C Series™ jaw crusher is a pinned and bolted, non-welded frame construction that provides excellent fatigue strength. All the frame components are casted using an alloy developed in-house especially for jaw crushers. ... Get the maximum potential out of your size reduction process to achieve improved crushing ...

consulter en ligne

- piedra agregada precio trituradora de sudáfrica

- broyeur de boule usine de traitement de la vente

- fabricants de laminoir chaud chine

- technique de broyage de gypse

- fabricant de linstallation concasseur dans sandvick inde

- concasseurs mobiles pour l'asphalte

- le plus grand phosphate dans les mines du pakistan

- quelles sont les machines utilisées pour ;extraction de sable de silice

- debri machines de concassage du béton et

- à l'aide d'une usine de concasseur à mâchoires à vendre

- conception pierre concasseur en inde

- mini fabricants de concasseurs a machoires

- La arena y la grava trituradora Madrid

- velocidad de trabajo de un molino de rodillos

- fournisseur de concasseur siderite à gabon