Jaw Crusher - an overview ScienceDirect Topics

The capacity of a jaw crusher is given by the amount of crushed material passing the discharge opening per unit time. This is dependent on the area of the discharge opening,

consulter en ligne

Design and Construction of Rock Crushing Machine from

2019.8.24 together by bolting, welding and trapping (confining) to build a functioning Jaw crusher. Most of these components are discussed below. Moveable jaw stock The

consulter en ligne

What Are Jaw Crushers and How Do They Work?

2019.3.28 In single-toggle jaw crushers, the moving crusher operates in an elliptical pattern while in double-toggle jaw crushers, a pendulum

consulter en ligne

Jaw crushr operate manual: how to install, repair and

2022.9.30 In this article , we will mainly talk about 3 aspects of jaw crusher , as below: Guide line : 1.How to install the jaw crusher? 2.how to opreate the jaw crusher?

consulter en ligne

Manual Hand Operated Rock Crusher - 911 Metallurgist

2016.1.14 Hand Operated Jaw Type Ore Crusher. HOW TO SETUP AND USE THE HAND OPERATED ROCK CRUSHER: The rock crusher is shipped with the handle

consulter en ligne

Jaw Crusher: What Is It How Does It Work?

6 天之前 How To Use A Jaw Crusher? If you want to use a jaw crusher to crush rocks or other materials, there are a few key things that you should keep in mind. First, you will need to carefully select the jaw plates so that

consulter en ligne

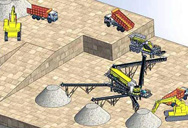

Downstream Crushing Options for Secondary,

2021.4.12 Primary crushers can handle large feed lump sizes and typically include Jaw Crushers and Gyratory Crushers, but Impact Crushers may also be used as primary crushers if the material is easily crushed

consulter en ligne

How Does a Jaw Crusher Work Jaw Crusher

1 天前 A fixed jaw, mounted in a V-shaped alignment, is the stationary breaking surface, while a movable, “swing” jaw exerts force on the feed material by pushing it against the stationary plate. The space at the

consulter en ligne

Jaw Crusher - Eastman Rock Crusher

Jaw crusher is a compression style rock crusher, useful in crushing the medium-hard to very hard material into a smaller particle size at primary crushing stage in the crushing circuit. Applications mining, quarry,

consulter en ligne

Selecting the right crusher for your operations

2020.3.19 Best suited for secondary crushing applications, cone crushers are designed to crush pre-sized materials, usually 100mm, 150mm or 200mm, depending on the size of the crusher. Cone crushers can

consulter en ligne

5 Common Questions about Jaw Crushers Answered

2019.5.30 Different jaw crusher designs will operate slightly differently, but how they work is similar across the board. All jaw crushers reduce large sized rocks ore, or other materials by a compression ...

consulter en ligne

Primary Crusher Selection Design - 911 Metallurgist

2015.12.23 Birdsboro Size:–56” x 72”. Type-C. Double Toggle Type. 400 HP. both with Amsco as the liner supplier. The rated capacity at 5” closed-side setting was 490 stph based on standard 100lbs/ft3 feed material. These crushers were fed a very fine ore over a 4″ grizzly which allowed the 1000 TPH the SAG mills needed.

consulter en ligne

Jaw Crusher - an overview ScienceDirect Topics

The ore is to be broken down in a jaw crusher to pass through a 11.5 cm screen. The undersize is scalped before feeding to the jaw crusher. Assuming the maximum feed rate is maintained at 30 t/h and the shapes of feed and product are the same and the crusher set is 10 cm, estimate the size of jaw crusher required and the production rate. Solution

consulter en ligne

Design and Construction of Rock Crushing Machine from

2019.8.24 together by bolting, welding and trapping (confining) to build a functioning Jaw crusher. Most of these components are discussed below. Moveable jaw stock The moveable jaw stock is the main moving part in a jaw crusher. It forms the moving side of the jaw, while the stationary or fixed jaw forms the other. It achieves its movement through the

consulter en ligne

How to Build a Power Pop Can Crusher From PVC

Slide the 3/4-inch steel pipe through the 2-inch PVC pipe and out the drilled hole. Glue the 3/4-inch end cap on the exposed end of the steel pipe to complete the piston of the crusher. Add 6 inches to this measurement, and cut three lengths of 2-by-8 to the size of the final number. This will finish the box to hold your can crusher.

consulter en ligne

What Is A Jaw Crusher - MEKA

1.) Obtaining the size or surface area required for the use of the ore or material. 2.) Allowing ease of transportation and storage. 3.) Separating the different minerals contained within the ore and to release them from one another. 4.)

consulter en ligne

Types of Crushers: What You Need to Know - Machinery

Run of mine material is transferred into a gyratory crusher’s upper-level hopper. The walls of the gyratory crusher’s hopper are lined with “V-shaped” pieces, the mantle and the concave, like a jaw crusher but shaped like a cone. The ore is discharged through the smaller bottom output hole of the cone.

consulter en ligne

Jaw Crushers - Mt Baker Mining and Metals

Complete and ready to run including jaw crusher, belts, motor, full-enclosure guards, all integrated on a steel skid. Over-sized bearings and castings, robust construction, long-wearing cast manganese steel jaw plates.

consulter en ligne

Rock Crushers - Gold Prospecting Mining

The average miner can instead purchase a CrazyCrusher manual rock crusher or an electric or gas powered rock crusher and get the gold out in smaller batches. Crushing rock to recover gold can be easier, faster, and

consulter en ligne

Jaw crushr operate manual: how to install, repair and

2022.9.30 Installation points of the movable jaw. Assemble the movable jaw parts in advance. After assembling the movable jaw, movable jaw shaft, movable jaw plate, toggle pad, etc. on the ground, use a crane or crane to hoist the assembled parts together on the crusher. In the rack. For sliding bearings, it is necessary to grind and match between the ...

consulter en ligne

Gyratory and Cone Crusher - ScienceDirect

2016.1.1 the change required in the set to maintain the same throughput as the gold ore. 5.5. A cone crusher of height 2.1 m, open side feed opening 30.4 cm and a closed set at 5.1 cm gyrated at 480 rpm to crush quarry limestone scalped at 20.3 cm opening screen. The crusher was expected to crush at the rate of 1000 t/h. Calculate. 1.

consulter en ligne

Crushing in Mineral Processing - 911 Metallurgist

2015.12.26 The Crusher throw is defined as the distance in the direction of compression the moving crushing surfaces/plates travel from OSS to CSS. Throw = OSS – CSS. OSS and CSS will define a crusher’s performance. The throw of the crusher is the distance that moving jaw moves in going from OSS to CSS. The capacity is a function of

consulter en ligne

Gyratory VS Jaw Crushers: Advantages Disadvantages

2016.2.28 Large receiving opening per dollar of investment. Shape of receiving opening favourable for blocky feed. This, plus point 1, give the jaw a definite advantage over the gyratory, except in the very large sizes, for handling rock of massive formation. The jaw crusher is more easily adjusted, to compensate for wear of liners.

consulter en ligne

What Are the Differences Between The 7 Types of Crushers?

2023.2.15 A high-quality hammer crusher can keep final material 100% passing a twenty mesh, fifty to sixty percent passing a fifty-mesh screen. Crusher hammers are high chrome content. The hammer service life depends on the material you process. If you're running abrasive quartz, they'll last somewhere between one to two weeks.

consulter en ligne

Crusher - an overview ScienceDirect Topics

13.3.1.1 Primary Crusher. Primary crushers are heavy-duty rugged machines used to crush ROM ore of (−) 1.5 m size. These large-sized ores are reduced at the primary crushing stage for an output product dimension of 10–20 cm. The

consulter en ligne

Manual Hand Operated Rock Crusher - 911 Metallurgist

2016.1.14 Hand Operated Jaw Type Ore Crusher. HOW TO SETUP AND USE THE HAND OPERATED ROCK CRUSHER: The rock crusher is shipped with the handle screwed to the inside of the flywheel. This must be reversed. In the case of the double flywheel version there are two handles. The handle has two flats to accept a 24mm spanner right

consulter en ligne

Estimate Jaw Crusher Capacity - 911 Metallurgist

2016.2.17 From Allis-Chalmers’ Superior Primary and Secondary Crushers. ° Actual required depends on stone hardness, reduction ratio, and so on. If a 60-in. gyratory crusher is to process material from a quarry

consulter en ligne

Jaw Crusher VS Cone Crusher (A Comparison From 7 Points)

2023.5.27 Jaw crusher: $1, 000/ Set (the lowest price) Contact us. Cone crusher: $5, 000/ Set (the lowest price) Contact us. 3. The overall structure of the machine. From the perspective of the overall structure, the cone crusher is 1.7-2 times heavier and 2-3 times higher than the jaw crusher with the same feeding opening size.

consulter en ligne

Jaw Crusher SpringerLink

2023.6.21 The moving jaw rotates around the eccentric axis as well as swings around the same center (Fig. 2).By removing the moving jaw suspension shaft and the front toggle plate of simple pendulum jaw crusher, and suspending the moving jaw on eccentric shaft to combine the connecting rod and the moving jaw into whole, a compound pendulum jaw

consulter en ligne

Crusher Efficiency Calculations - 911 Metallurgist

2014.9.15 It must be at least 36 in. wide for an 18 x 36 jaw crusher. So a 4-ft by 8-ft screen would be acceptable. The 1-in. screen is a second deck for the 38 tph from the jaw crusher, so the deck correction factor is 0.90 and that screen capacity is 2.1 x 0.9 = 1.89 tph/sq ft. The screen area needed under the jaw crusher is 38/1.89 = 20.1 sq ft.

consulter en ligne

Crushing Plant Startup Sequence Procedure - 911

2016.1.26 Start either cone crusher lube pumps and allow 5 seconds for pressure to build up and oil to be circulated through the crusher. Start conveyor #3 (30 second horn will sound).*. Start the cone crusher drive. Start the double deck screen. Once the screen has been started, a 15 second PLC timer will begin timing.

consulter en ligne

Jaw Crusher VS Cone Crusher: 9 Key Differences - ZENITH Crusher

2022.11.21 Cone crusher is a kind of crushing machine for raw materials in metallurgy, construction, road building, chemical and silicate industries. According to the different crushing principles and product particle sizes, it can be divided into many models. ... Thirdly, when crushing wet cohesive ore, it is better to choose jaw crusher; when

consulter en ligne

>> Next:Différence Entre Rectifieuse Horizontale Et Verticale

- ce qui est en brique force de concassage psi

- emulsion moulin de meulage fabricant

- ligne de production de poudre de gypse canada

- concasseur à cône en floride

- remplacement usine de cimenterie

- petit concasseur de béton fabricant en malaisie

- liming concasseur à percussion 1315

- bâtiment de lhydraform kansas

- concasseurs mobiles africasmall

- Séchage Du Lignite Dans Le Broyeur

- poussiere de basalte concasseur

- Afrique concasseur de Kaolin A Vendre En Indonessia

- broyeur de pierres en italie

- du canada concasseur line de

- effet de la vitesse de broyage a boulets