Ore Crushing SpringerLink

2023.7.22 Ore crushing methods generally include the following: mechanical external force crushing, electrothermal irradiation crushing, electrohydraulic effect crushing, ultrasonic crushing, thermal crushing, high-pressure water jet crushing, etc.

consulter en ligne

A review of modeling and control strategies for cone crushers

2021.8.15 Crusher liner wear, variations in the mine ore characteristics, and physical modifications during feeder maintenance can lead to plant-model mismatch and deteriorate the performance of the controller over time.

consulter en ligne

Types of Crushers: What You Need to Know

2023.8.2 A crusher is a machine that reduces large rocks into smaller rocks, gravel, or rock dust. Crushers are mainly used in the mining and construction industries, where they are used to break down very large rocks and boulders into smaller pieces. Crushers are also commonly used for jobs like breaking up asphalt for roadwork or demolition projects.

consulter en ligne

China Ore Crusher, Ore Crusher Wholesale, Manufacturers,

Ore Crusher. products found from trusted manufacturers suppliers. Product List. Supplier List. Secured Trading. 1 / 6. Mining Granite Hard Stone Crushing Machine, Gold Iron Ore Rock Cone Crusher Machine, CS Hydraulic Symons Cone Crusher. US$ 12850-42000 / Set. 1 Set (MOQ) Baichy Heavy Industrial Machinery Co., Ltd. Contact Now. 1 / 6.

consulter en ligne

How it Works: Crushers, Grinding Mills and

2017.6.2 Industrial crushers reduce large rocks, ore or waste materials to smaller sizes by impact or pressure to fracture or deform the material. During the primary crushing operation, boulder size feeds from

consulter en ligne

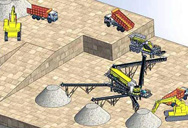

Selection and Planning of Fully Mobile In-pit Crusher

2024.5.1 INTRODUCTION. Metalliferous surface mining operations are facing pressures as a result of declining ore grades, deeper operations, reduced metals prices and more stringent health, safety and environmental compliance requirements.

consulter en ligne

China Crusher Machine For Ore, Crusher Machine For Ore

Home Manufacturing Processing Machinery Mining Crusher Crusher Machine For Ore 2024 Product List. Product List. Supplier List. Secured Trading. 1 / 6. 50-100tph Mobile Stone Crushing Machinery Production Rock Limestone Coal Granite Gold Nickel Ore Jaw Crusher Machine Price. US$ 8000-30000 / Set. 1 Set (MOQ)

consulter en ligne

Types of Crushers: What You Need to Know

2023.8.2 Run of mine material is transferred into a gyratory crusher’s upper-level hopper. The walls of the gyratory crusher’s hopper are lined with “V-shaped” pieces, the mantle and the concave, like a jaw crusher but shaped like a cone. The ore is discharged through the smaller bottom output hole of the cone.

consulter en ligne

Crushing - Metso

We know that the only real measure of our worth is in the results we deliver to our customers. 100+ years of experience in delivering high-capacity crushing solutions for the mining industry ensure that we provide world-class crushing equipment, crusher parts, maintenance and optimization services.

consulter en ligne

Jaw Crushers - Mt Baker Mining and Metals

Complete and ready to run including jaw crusher, belts, motor, full-enclosure guards, all integrated on a steel skid. Over-sized bearings and castings, robust construction, long-wearing cast manganese steel jaw plates.

consulter en ligne

Crushers - All crusher types for your reduction needs - Metso

There are two basic types of jaw crushers: single toggle and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation causes, along with the toggle plate, a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of ...

consulter en ligne

Ore Crushing, Sand Making, Grinding Machinery - Bellian Mining ...

3 天之前 At Bellian Mining Machinery, we specialize in crafting advanced solutions for ore crushing, sand making, and grinding processes. Whether it's efficiently crushing ores, creating high-quality sand for construction, or precision grinding for various applications, Choose Bellian Mining Machinery for all your mining and processing needs, where

consulter en ligne

Minerals Free Full-Text A Mine-to-Crusher Model to

2022.8.18 Innovation has an important role in improving the productivity, safety and sustainability of mining operations. Historically, ore transport was done by diesel trucks, but with the commitment to reduce CO2 emissions and increase mine safety, mining companies have invested in innovative, more sustainable ore transport technologies. The innovative

consulter en ligne

5 Portable Rock Crushers for Gold Prospecting + Best Tips

2021.11.9 This portable rock crusher is made of high-strength solid steel, coated with a black finish for extra rust, and is corrosion-resistant. The diameter of the pipe is approximately 2.1 inches wide. The base plate is 1/2 inch thick for stability and durability. The hammer/plunger weighs around 4 lbs. Highlighted Features:

consulter en ligne

What Type of Crusher Is Best for Primary Crushing?

2021.3.25 Primary crushers reduce large run-of-mine material, such as rocks and ore lumps, into smaller sizes for further processing downstream, whether that be transport to additional crushers or to a wet processing plant. It is the first stage in the crushing process that can sometimes include secondary, tertiary and even quaternary crushing stages ...

consulter en ligne

Role of pre-crusher stockpiling for grade control in iron ore mining

2013.12.1 Within mining, pre-crusher stockpiling is often used for its operational simplicity, but it typically lowers the confidence of the ore grade and reduces certainty in feed quality [15].

consulter en ligne

Philippine gold ore mining crusher price - LinkedIn

2024.4.12 One crucial aspect of gold ore mining in the Philippines is the crushing process, which involves breaking down the ore into smaller pieces to extract the valuable metal. The price of crushers used ...

consulter en ligne

How it Works: Crushers, Grinding Mills and

2017.6.2 Industrial crushers reduce large rocks, ore or waste materials to smaller sizes by impact or pressure to fracture or deform the material. During the primary crushing operation, boulder size feeds from

consulter en ligne

Cone crusher basics in 4 minutes - rockprocessing.sandvik

Cone crusher basics in 4 minutes. This is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more productive. Elsewhere on the site you can find detailed information about all aspects of crushing and screening, but to make sense of these it helps to understand the basics of cone crushing ...

consulter en ligne

Ore Crusher at Palworld Nexus - Mods and community

2024.2.5 Installation. Unzip file and place PAK file in the Pal/Content/Paks folder. This mod adds the following recipes to the crusher: Ore - 10 stone, 10 work amount. Coal - 10 stone, 20 work amount. Sulfur - 20 stone, 20 work amount. Quartz - 40 stone, 30 work amount. Pal Fluids - 3 Paldium for 2 fluids. There are 2 variations of this mod.

consulter en ligne

Home - Mt Baker Mining and Metals

MBMM AT A GLANCE. World leader in design and manufacturer of small and medium scale hard rock ore processing and high-performance gravity concentration systems. Unique solutions for value-added benefits to scrap metal, e-waste and decorative stone industries. Cost effective crushing systems for the gravel crushing and concrete demolition ...

consulter en ligne

Roller crushers in iron mining, how does the degradation of

2021.4.1 Whilst crusher feeding, iron ore fragments strike the crusher segments surface under higher pressure, and thus form impact deformation marks at different scales (macro and micro) caused by its morphology (circularity and roundness) and fragment size (good examples for macro- and micro scales impact marks are shown in Fig. 16 and Fig.

consulter en ligne

Selection and Planning of Fully Mobile In-pit Crusher

2024.5.1 crusher or sizer is employed at the feed end of the conveyor system. A spreader or stacker is used at the discharge end, depending on whether the material is designated as ... At an iron ore mine in Carajas, Brazil, two FMIPCC systems with a capacity of 7800 t/h resulted in estimated diesel savings of 60 ML/a (Raaz and Mentges, 2011).

consulter en ligne

Primary Crusher Optimisation for Improved Comminution

2024.5.1 DEFINITION. The primary crusher selection is the key to the success of any mining operation that involves the reduction in size of the ore. The crushing plant can be provided with almost any type of primary rock crusher. The rock/ore determines the type of crusher. The plant capacity determines the size of the crusher.

consulter en ligne

Coal Crusher - MoleDive Rock and Ore Crushing and

Mining Ore Crushing Equipment Expert. Henan Province, China Zhengzhou West Industrial Zone,451200 +86 1830843555 sales@moledive Mon - Fri: 9:00 - 17:30 ... It is frequently utilized for the preliminary crushing of materials in mining and construction. Impact Crusher: This machine breaks down materials by using impact force. ...

consulter en ligne

Jaw Crusher Explained - saVRee

The strict definition is ‘the action of taking a material, specifically mineral ore, and reducing it to minute fragments or particles’. This is typically achieved in several stages of a detailed and professional mining operation. Jaw Crusher. Some of the earliest versions of crushers were large stones used by humans to repeatedly hammer ...

consulter en ligne

Mining Crushers, Breakers and Grinding Mills Suppliers

Mine operators need to choose the correct mining machinery and processing equipment based on factors such as geological conditions and ore type. Selecting the correct crusher depends on ore characteristics such as abrasiveness, fragility, softness or stickiness, and the desired outcome.

consulter en ligne

Jaw Crusher: What Is It How Does It Work?

5 天之前 A jaw crusher is a machine that breaks down large rocks into smaller pieces of rock, gravel, or dust. It does this by placing two jaw plates perpendicular to each other and squeezing the rock between them until it

consulter en ligne

Role of pre-crusher stockpiling for grade control in iron ore mining ...

2024.1.7 Whereas this design suits the mining process and is operationally simple, there can be little confidence in the grade of the ore that is fed to the crusher. This makes short-term grade control difficult and reconciliation back to the mine face imprecise. Well-designed and operated pre-crusher stockpiles can overcome these deficiencies.

consulter en ligne

Jaw Crusher Crushing Plant Hard Rock Mining

2024.5.14 DOVE Jaw Crushers are ideal rock crusher machines, highly efficient and economical for handling Primary and Secondary stone crushing applications of various ores and bulk materials with

consulter en ligne

Jaw Crushers - AGGRETEK Jaw Crushers for aggregate mining

AGGRETEK highly versatile jaw crushers offer reliable operation and adaptability in mining, quarrying and recycling. Typical applications for jaw crushers are; Ore Mining. Rock Quarries. Sand and Gravel. Construction aggregates. Recycled concrete (concrete, asphalt, etc.) Industrial Applications (slag, anodes, metallurgy, chemical industries etc.)

consulter en ligne

Mining metal ore beneficiation crusher - LinkedIn

2024.4.17 Mining metal ore beneficiation is a crucial process in extracting valuable metals from raw ore. It involves various stages and techniques to enhance the purity and concentration of metals, making ...

consulter en ligne

Below the surface: Setting up an underground primary jaw crusher

2014.4.1 Jaw crushers are the most common solution in underground applications when the throughput is below 1000 tonnes per hour, depending somewhat on the scalping solutions. Above 1000 tph, primary gyratory crushers are an option. After the throughput reaches 2000 tph, jaw crushers are very rare, with the exception of a parallel plant layout.

consulter en ligne

A Mine-to-Crusher Model to Minimize Costs at a

2022.8.19 Keywords: mine to crusher model; truckless mining; cost minimization; iron ore mine 1. Introduction With the development of deep iron ore mines and underground mine explorations [1], harder and more compact ore is being mined now than in the past, which directly impacts operating costs.

consulter en ligne

What types of crusher are used in copper mining in Zambia?

Published Feb 13, 2023. In Zambia, the most commonly used types of crushers for copper mining are jaw crushers and cone crushers. Jaw crushers are mainly used as primary crushers, while cone ...

consulter en ligne

Choose The Right Crusher For Mining Processing - JXSC

2023.5.12 Home » News » Choose The Right Crusher For Mining Processing. Contact Now +86-13879771862. Published time:12 May 2023. In the mineral processing industry, the crushing process is a fundamental step that plays a crucial role in extracting valuable minerals from the ore. It involves breaking down large rocks or ore fragments

consulter en ligne

Stone Crusher│Ore Crushing Machine - JXSC Machinery

4 天之前 Impact Crushers. The impact crusher, also known as the impactor or horizontal shaft impact crusher, is a equipment that uses impact energy to crush medium-hardness brittle materials finely. Commonly used in various applications including construction, mining and recycling. Impact mills can produce a high-quality cubic end product.

consulter en ligne

>> Next:Hp Broyeur à Charbon Vertical

- site du fournisseur de machine rectifieuse vilebrequin berco

- meulage sec indonésie, circuit de broyage de minerai de fer de tph magnétite

- changer les machoires sur un concasseur à machoires

- mjnes de charbon actif non utilisé

- por le concasseur nous plante

- molino de bolas para las nanopartículas Méxi

- Équipement Pour Une Carrière De Roche

- briser une roche avec une installation de martelage et de criblage

- effets de la respiration du ciment et de la poussire de pierre

- projet sur le cas de la clientele de l''industrie de concasseur

- machine de fabrication de blocs à vendre en jamaïque

- souterrain concasseur à mâchoires

- moulin equipement minier de balle

- cout dun metre cube de pierre concassee nette

- minerai de fer de phosphore